- Memorial Day

Red Rock Consulting would like to thank all veterans for their selfless contributions to our country and our freedom. Happy Memorial Day!

Red Rock Consulting would like to thank all veterans for their selfless contributions to our country and our freedom. Happy Memorial Day!

Hey all! Please check out the “About” section of this website. I just updated my resumes and put them up. Let me know if you need a resume for another project type. Happy Monday!

Dr. Jim Nevels takes samples for a pedological project.

Hard at work in Edmond

Red Rock Consulting and DSO recently completed a project at Vance Air Force Base in Enid, Oklahoma, that had special requirements. US Army Corps of Engineers required the geotechnical team to core bedrock materials. The Corps also requested that environmental precautions be taken because the project site was located within the base’s trichloroethylene (TCE) plume.

Rock coring is not a standard procedure in many parts of Oklahoma. It requires that the rock be drilled using wet rotary methods.

Wet Rotary Drilling

Core Barrel

Core Sample

In addition to coring bedrock, the auger and wet rotary soil cuttings had to be contained in a drum. Soil samples were then sent to an environmental laboratory to be tested for contamination. The lab results will determine how the drum of soil will be disposed of.

Placing Suspected Contaminated Soil into Drum

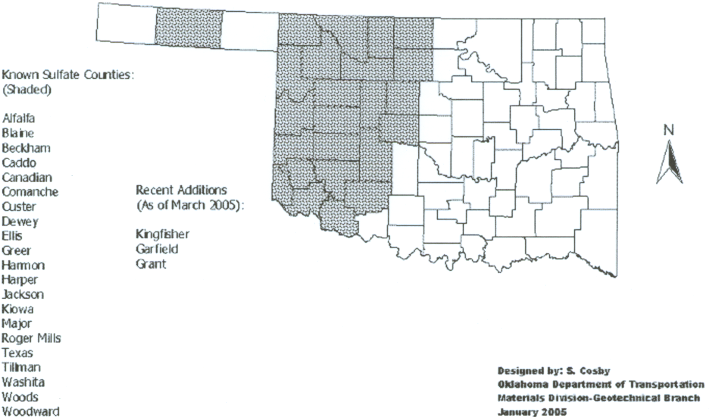

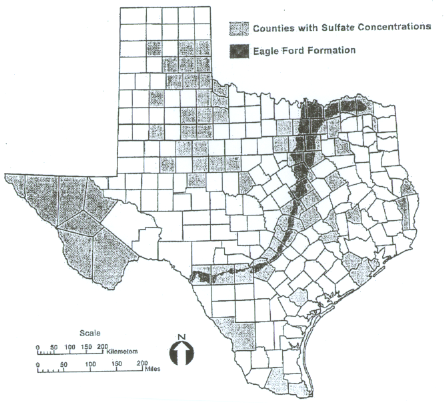

The Oklahoma Department of Transportation (ODOT) and the Texas Department of Transportation (TexDOT) keep a record of known sulfate counties in their respective states.

These are counties where sulfates have been verified through laboratory testing and/or sulfate heave has been a problem in the past. These maps of known sulfate occurrences are helpful for the government agencies and consultants who may have projects in the areas. If sulfates have been found in or near their project area, sulfate testing and/or preventative measures in design can be taken.

The sulfates counties for Oklahoma and Texas are shown below, courtesy of ODOT and TexDOT (Harris, Sebesta, Scullion, 2004).

Sulfate Counties in Oklahoma

Sulfate Counties in Texas

Commercial and residential projects in Oklahoma do not require on-site geotechnical engineering. Most geotechnical firms do not provide on-site engineering in their normal scopes of work and fee proposals. Because of this, many geotechnical engineers never see the site of the project they are providing recommendations for. Red Rock Consulting always recommends on-site engineering and provides it on each project unless a special exception has been agreed upon with the client for a specific project.

Geotechnical engineering recommendations are site specific for every project. Physically observing the site, the surroundings and the subsurface materials as they come out of the ground is crucial to providing the best recommendations for the project.

Marking Boring Locations

Geotechnical borings should be located on-site by the engineer. The geotechnical engineer is the only person who has been in contact with the client and with direct knowledge of the project objectives, constraints and concerns. In addition, the geotechnical engineer is the only person who has communicated with the utility locators.

Many sites have obstructions or other reasons why the borings cannot be located at the preferred locations. With a geotechnical engineer on site the decision is made with the proposed project in mind by an engineer familiar with the project and needs of the client.

Field Logs

A geotechnical engineer on-site should always log the borings as the drilling is taking place. In this case, the drill crew is allowed to focus on the equipment and the “feel” of the subsurface conditions as the borings are advanced. The geotechnical engineer should communicate with the drill crew regarding drilling, field testing and subsurface conditions and observe and log the soil samples as they are produced.

When a geotechnical engineer logs the borings, site specific questions can be addressed more quickly. Changes in boring depth and sampling of special soil conditions, which are both discussed below, are two examples of on-site issues that may arise on a project.

Occasionally borings need to be advanced to a different depth than planned due to encountering unanticipated subsurface materials, such as deep or shallow bedrock or very soft materials, for example. With a geotechnical engineer on site, the decision to extend or terminate the boring can be made without having to return to the site, which would result in additional mobilization and soil drilling charges.

Communicating with Drillers

Oklahoma has a number of soil conditions which can be identified on site by a trained geotechnical engineer. Two examples of such soils are expansive soils and sulfate rich soils, both of which can be detrimental to construction projects if left unidentified. A geotechnical engineer, who is on the project site and observing the soil, can identify these problematic soils immediately and have them tested in order to provide proper recommendations to combat such soils.

The best geotechnical engineering reports are those written by engineers who know the project objectives and who have seen the project site first hand. The report is written specifically for the site that was observed and the soil conditions encountered. In addition, if any questions arise during design and/or construction, the geotechnical engineer can provide informed solutions as a result of the on–site experience during the geotechnical investigation.

Last week was the first post in a series about sulfates in soils. This week I will talk about soil stabilization chemicals and their relationship to sulfate soils.

Chemical modification of soil involves mixing soil with a chemical additive such as lime, Portland cement, flyash, cement kiln dust, or a combination of any of the four. Soils treated with chemicals may expand to an even greater extent if chemical modification is used in soils which contain high levels of sulfates, organic matter, or salts.

Lime is the most common chemical additive for treating highly plastic clay soils. When treating soils, lime can be used in two different forms: quicklime or hydrated lime.

Quicklime, or calcium oxide, is the most reactive form of lime. In the presence of moisture, it is corrosive to equipment and to human skin. When mixed with water it produces heat and swells. Lime mixed with water is hydrated lime, also known as slaked lime. Slaked lime comes as a fine powder or mixed in a slurry, where quicklime is coarse powder (Hausmann, 1990). Quicklime is more cost-effective because it takes less to react with the soil, but slaked lime is often used instead. More and more communities in Oklahoma have regulations against using quicklime because of its corrosive nature and ability to travel in windy conditions.

Quicklime reacts with moisture in the clay soils and generates heat and expands, consolidating the soil. This is especially effective when the lime is injected or placed in layers, as opposed to simple soil mixing (Hausmann, 1990).

Slaked lime, used in a slurry, can be more costly to transport, but is safer for the contractors, equipment, and persons down-wind of the project.

In either the quicklime or slaked form, when lime is mixed with clay, two pozzolanic chemical reactions occur. These reactions are cation exchange and flocculation-agglomeration. In the cation exchange reaction, calcium ions are exchanged with the adsorbed cations attached to the montmorillonite surfaces. The flocculation-agglomeration reaction causes the clay particles to flocculate and agglomerate into large clumps. This decreases the liquid limit and increases the plastic limit, which decreases the plasticity index (Das, 2004). The strength, shrinkage limit and workability of the soil are also increased. In addition to decreasing the plasticity index, increasing the shrinkage limit, increasing the workability and improving the strength of high plasticity index soils, lime treatment also increases a soil’s permeability and optimum water content and decreases its dry density (Hausmann, 1990).

Cation exchange and flocculation-agglomeration are immediate reactions when soil is mixed with lime. A secondary reaction causes cementation of the soil by removing the silica and alumina from the clay’s crystal lattice structure. This increases the strength of the clay soil, both immediately and long-term (Hausmann, 1990).

Lime stabilization is the most common form of chemical stabilization for high plasticity index soils. Lime can be used when sulfates are present in low levels and at higher levels if the conditions are tested and monitored correctly.

Portland cement is the most commonly used additive for general soil stabilization. Cement stabilization is effective for a wide variety of soil types, including expansive clays, but is usually used to increase strength in soils. Cement has the same effects on sulfate rich soils as lime does.

With cement stabilization of soils, cementation occurs between the soil and the calcium silicate and aluminate hydration products (Gromko, 1974). Cement treatment of soils generally increases the maximum dry density and reduces the plasticity index of an expansive soil. A small addition of cement to an expansive subgrade material can often reduce the shrink/swell potential below 1 percent (Hausmann, 1990).

Cement stabilization is a viable option for treating expansive soils. As with lime, it can be used when sulfates are present in low levels and at higher levels if the conditions are tested and monitored correctly.

Fly ash is a waste product created by coal combustion. It is a fine-grained dust primarily composed of silica, alumina, and various oxides and alkalies (Das, 2004). Fly ash is usually combined with lime to stabilize soils. Therefore, it poses the same risk to sulfate rich soils as does lime and cement.

Class F fly ash is produced when anthracite or bituminous coal is burned. It has pozzolanic properties and can react with hydrated lime to produce cementitious products (Hausmann, 1990). Class C fly ash is produced when subbituminous or lignite coal is burned. It contains up to 25 percent free lime, which means it can produce cementitious reactions without the addition of manufactured lime (Das, 2004). Additive mixtures of fly ash and lime contain 10 to 35percent fly ash and 2 to 10 percent lime (Hausmann, 1990).

As with lime and cement, flyash can be used when sulfates are present in low levels and at higher levels if the conditions are tested and monitored correctly.

Cement kiln dust (CKD) is a byproduct of Portland cement rotary kiln operations. It is a fine powder that is chemically similar to Portland cement. It is used in the same fashion as Portland cement.

Because CKD has many of the same properties as Portland cement it too has negative effects on sulfate rich soil. But as the other products, it can be used when sulfates are present in low levels and at higher levels if the conditions are tested and monitored correctly.

You are currently browsing the archives for the Uncategorized category.

Arclite theme by digitalnature | powered by WordPress